The Process Technology Blog provides educational and product information for the industrial process control and factory automation markets. Posts will include application information, new product announcements, How-To's, and process control education. This blog is sponsored by Process Technology, Inc. Contact PTI by calling 801-264-1114 or visiting their website at https://process-tech.com.

A Wafer Style Control Valve with a Modular & Stackable Actuator: The Jordan Mark 75A

The Hach SC4500 Digital Controller

Technologies are continually evolving, bringing new levels of ease, precision, and efficiency to the market. That's why the Hach® SC4500 Controller fits seamlessly into your existing system while also allowing you to upgrade as your capabilities grow without having to replace inventory. The SC4500 opens the future now with a wide choice of analog and digital connectivity options and clever instrument and data management functions.

For more information about Hach products in Colorado, Eastern Wyoming, Montana contact Process Technology, Inc. Call 801-264-1114 or visit https://process-tech.com.

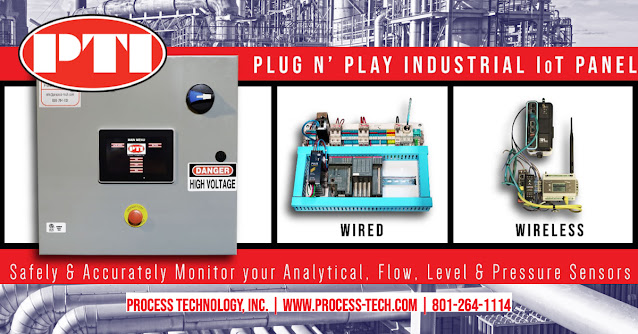

IIoT Control Panel Solutions from Process Technologies

Increase the efficiency of operations while lowering costs with a wireless or connected control panel that can monitor compressors, generators, tank levels, pressure, temperature, and vibration. Analytical sensors and flow, level, and pressure sensors are all monitored safely and accurately. Plug n Play alternatives customized for your application are available.

PTI creates high-quality electrical control panels in a short amount of time, using the most reliable and cutting-edge hardware available. PTI also provides software development services to accommodate our customers' increasing demands with turnkey solutions, in addition to solid panel design and fabrication capabilities.

Using cutting-edge technology, Process Technologies can incorporate the Industrial Internet of Things (IIoT) into panel builds to give real-time dashboards and analytics, allowing customers to monitor system status and real-time data from anywhere in the world.

PTI sales engineers will meet with you on-site to discuss your requirements, evaluate, design, and execute a complete cost-effective solution kit to automate your process and factory automation application needs.

Contact PTI today to discuss you IIoT control panel requirements. Call 801-264-1114 or visit https://process-tech.com.

Application Note: Transparent Bottle Detection in a Washdown Environment

This application involves regulating conveyor line pressure by monitoring clear bottles.

When bottles on a conveyor touch and move together, the conveyor's force multiplies by the number of bottles, creating line pressure. The stored energy in the line pressure can cause product damage and loss, which means additional costs and delays. Regulating line pressure on beverage filling lines is critical. A sensor that can identify transparent or shiny objects and transmit a signal to the control when they amass is required. So that more containers can be added upstream till the bottles flow again.

The Q4X laser clear object detection sensor from Banner Engineering can detect clear objects without using a reflector. For reliable detection of challenging targets such as bottles and cans, it decides on the presence of a target based on both distance and intensity. By removing a reflector from a washdown area, you are also releasing a potential point of failure. The sensor has built-in on/off delays that ignore passing bottles while sending a signal if a bottle is still present or accumulation occurs.

The Q4X COD laser sensor can detect a broader range of transparent objects and is built with sealed IP69K-rated stainless steel housing, making it an ideal choice for the beverage industry.

Banner is the leading manufacturer of photoelectric devices, machine safety devices, vision sensors, and wireless I/O systems. For more information about Banner products in Utah, Western Wyoming, Idaho, Northern Nevada, Colorado, Eastern Wyoming, and Montana, contact Process Technology, Inc. Call 801-264-1114 or visit https://process-tech.com.

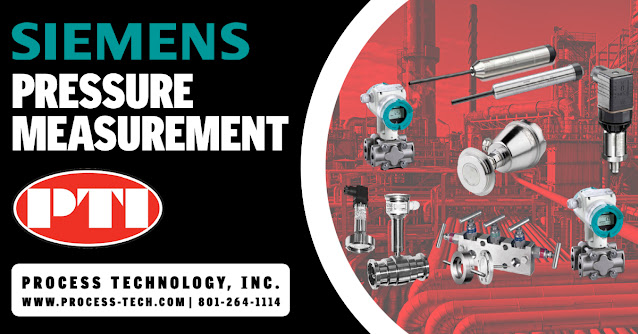

Siemens Industrial Pressure Measurement Transmitters

Siemens SITRANS P pressure transmitters are a comprehensive family of gauge, differential, and absolute pressure measurement instruments with a wide range of performance values, load capacities, and materials. The modular system offers excellent operating simplicity and practicality, as well as optimum safety, in addition to high measuring accuracy and robustness. Siemens transmitters address the obstacles posed by increasingly complicated operations in the process industries.

The most critical factor in selecting a suitable pressure transmitter is the required accuracy of the measuring range. SITRANS P transmitters offer a variety of choices from 0.03 percent to 0.3 percent. They’re ideal for safety-related applications, with certifications according to SIL2 and SIL2/3.

Gauge, absolute, and differential pressure must be monitored continuously for gases, liquids, and paste-like media to detect values that are too low or a potential overload.

HART®, PROFIBUS PA, and FOUNDATION Fieldbus are just a few of the communication bus systems supported. SITRANS P pressure transmitters also have all of the most recent approvals and certificates.

Siemens pressure measurement instruments provide the instrumentation reliability you require to satisfy your facility's individual needs.

For more information about Siemens products in in Utah, Western Wyoming, Idaho, Northern Nevada, Arizona, New Mexico, Colorado, Eastern Wyoming, and Montana contact Process Technologies, Inc. Visit https://process-tech.com or call 801-264-1114.

The Tideflex TF-1 Check Valve

The TF-1 is the most popular Tideflex Check Valve configuration for outfalls. The TF-1 has a flat bottom and a flared top designed for in-structure and end-of-pipe installations. As a result, the valve can be installed at a lower overall elevation than in other configurations, requiring less bottom clearance.

The TF-1 is ideal for maintenance hole applications such as junction boxes, diversion chambers, and interceptors where the pipe invert is close to the vault floor. The invert pipe is as close to the floor as possible in these vaults to maximize the available gravity head. The TF-1 is designed to install within such structures and can be easily retrofitted to existing systems, frequently replacing failed flapgates.

For more information contact Process Technology, Inc.

801-264-1114

https://process-tech.com

The Jogler MGT-6000, ILT-6000, and LLT-1000 Electronic Level Transmitters

This video will describe the operation of the Jogler MGT-6000, ILT-6000 and LLT-1000. The ILT-6000 are both Magnetostrictive Level Transmitters, while the LLT-1000 is a LIDAR Level Transmitter.

The MGT-6000 Magnetostrictive Level Transmitter is a loop powered non-contact level measurement device that is mounted externally to a magnetic level gauge. Utilizing the magnetostrictive principle and time-of-flight calculations allow the MGT-6000 to provide a fast and accurate measurement of float position and, ultimately, liquid level in the gauge. Vibration-isolating elastomeric bushings ensure continuous operation in high vibration services.

The ILT-6000 Direct Insertion Magnetostrictive Level Transmitter is a loop powered non-contact level measurement device that can be installed directly into a process vessel. Utilizing the magnetostrictive principle and time-of-flight calculations allow the ILT-6000 to provide a fast and accurate measurement of float position and, ultimately, liquid level in the gauge. The ILT-6000 is installed in an isolation well assembly allowing the transmitter to be removed, serviced, or replaced with no process interruption.

The LLT-1000 LIDAR Level Transmitter is a non-contact, laser based instrument that measures the level of dry solids and opaque liquids in silos, tanks, hoppers, and other vessels. 4-20mA and relay outputs give the LLT-1000 the flexibility to be used in various control schemes.

For more information about Jogler products Utah, Western Wyoming, Idaho, Northern Nevada, Arizona and New Mexico contact Process Technology. Call them at 801-264-1114 or visit their web site at https://process-tech.com.

Hach Data Delivery Services (DDS)

Hach Data Delivery Services (DDS) is an all-inclusive, fixed-cost DDS flow monitoring package. It provides round-the-clock access to data you can share and on which you can act.

DDS allows you to stop wasting time attempting to obtain reliable flow data and instead begin implementing solutions that genuinely address your wastewater flow concerns. Hach DDS is a highly efficient flow monitoring service. Hach Flow will offer the equipment, resources, and support you need to gather your flow data for a flat monthly charge. And, with DDS, you can finally choose the structure of the service. If staffing isn't an issue, but funding for the most up-to-date and dependable monitoring technology is, DDS can help. DDS can also assist if you are tired of installing and maintaining flow monitoring equipment and want accurate — and fast — flow data without the fuss. Hach DDS empowers you with intelligent data, leaving the rest to us, with programs customized to tackle your specific pain areas – budget, technology, resources, or difficulty.

For more information in Colorado, Eastern Wyoming, and Montana contact Process Technology, Inc. Call them at 801-264-1114 or visit this link.

Improve Polyethylene Terephthalate (PET) Production with Siemens LR560 Level Transmitter

PET is an abbreviation for polyethylene terephthalate, which is the chemical term for polyester.

PET is a transparent, robust, and lightweight plastic widely used in packaging foods and beverages, particularly convenience-sized soft drinks, juices, and water. PET is used to make almost all single-serving and 2-liter bottles of carbonated soft drinks and water sold in the United States.

PET containers are produced in two stages, employing injection molding and blow molding machinery.

THE CHALLENGE OF PET LEVEL APPLICATIONS

Storage tank monitoring of crystalline PET plastic pellets used to make plastic soft drink bottles is essential. The crystalline pellets have a density ranging from 30 pounds per cubic foot to 56 pounds per cubic foot, and the storage tanks can be up to 60 feet tall.

Level measurement is crucial for inventory control and sustaining material availability during production times. If the inventory is running low, production needs to know whether or not tanks will need to swap.

Some plants measure levels with a plumb-bob, and some use ultrasonic level transmitters. The plumb bob cord becomes a mechanical inconvenience, and due to excessive dust levels, the ultrasonic level devices experience frequent echo loss.

THE SOLUTION: SIEMENS LR560 LEVEL TRANSMITTERS

The Siemens LR560 transmitter provides a continuous, consistent, and low-maintenance level measuring solution. The SITRANS LR560 unit's plug-and-play capability is appropriate for most solids level monitoring applications, even those requiring severe dust and high temperatures. Its one-of-a-kind design allows for safe and simple programming with the intrinsically safe handheld programmer without the need to open the instrument's lid.

THE SITRANS LR560'S BENEFITS

Savings in time

- Significantly reduced maintenance. Because the SITRANS LR560 radar transmitter is non-contact, there is no risk of product contamination or extended delays when plumb-bob cables become entangled or break.

Process dependability has increased.

- Continuous level measurement provides a precise temporal indicator of how much is in the silo. When a plumb-bob wire becomes trapped at a certain distance, the accurate level data is lost. There is no level history before the last on-demand request from the instrument after the line is attached.

Simpler to use

- The SITRANS LR560 transmitter employs a quick start wizard and requires no more calibration or maintenance.

UNIQUE PRODUCT FEATURES OF SITRANS LR560

The local user interface facilitates setting and setup. Customers can save money by shifting the indicating component from unit to unit as needed because they only use the removable, local display during setup. The narrow, 4-degree beam angle allows for consistent depth penetration into the silo while ignoring possible silo wall interference.

The SITRANS LR560 2-wire, 78 GHz FMCW radar level transmitter monitors solids in silos over a 100-meter (328-foot) range. Its plug-and-play performance is suited for most solids applications, including those with high temperatures up to +392oF and severe dust. Its one-of-a-kind design allows for safe and straightforward programming with the intrinsically safe handheld programmer without the need to open the instrument's lid.

The SITRANS LR560 transmitter offers an optional graphical local display interface (LDI) that facilitates setup and operation by providing diagnostic support via an intuitive Quick Start Wizard and echo profile display. The QuickStart wizard makes it simple to get started, with only a few parameters needed for basic functioning. The SITRANS LR560 equipment monitors almost any solids material level up to 328 feet.

Contact Process Technology, Inc. at 801-264-1114 or visit https://www.process-tech.com to discuss this or any other process instrument application.

The Mettler Toledo 6000TOCi Total Organic Carbon Analyzer

Total Organic Carbon (TOC) monitoring is critical for measuring and controlling organic contamination in pure and ultrapure waters. TOC monitoring is essential in the pharmaceuticals, microelectronics, and power generation sectors.

The 6000TOCi analyzer measures TOC levels in water systems quickly and continuously. 6000TOCi customers benefit from real-time data instead of batch systems that measure at intervals, guaranteeing that TOC excursions are never missed – even for a minute.

Mettler Toledo Thornton's 6000TOCi is a continuous measuring TOC (total organic carbon) sensor. In pure and ultrapure fluids, the sensor gives continuous, real-time data. It employs superior UV oxidation technology with a speedy response time.

The 6000TOCi Total Organic Carbon sensor has a response time of less than one minute. It allows continuous monitoring, which is a significant advantage over batch measurement systems, which can take six minutes or longer to produce a picture of water quality.

The 6000TOCi's real-time measurement capability enables you to preserve detailed records of trending, history, and critical information to support your compliance documents. You may keep a complete sensor history record by using the USB ports for printer and data logging.

The 6000TOCi meets the TOC instrumentation criteria of all significant worldwide pharmacopeias, including USP, EP, JP, ChP, and IP.

The 6000TOCi's versatility allows it to be installed anywhere on a water system, with the option of displaying results at the place of measurement or in a more convenient location for operators.

For more information contact Process Technology, Inc.

801-264-1114

https://process-tech.com

Industrial Level Monitoring and Control Instrumentation

Jogler is a manufacturer of high-quality Magnetic Level Gauges, Magnetostrictive Transmitters, Direct-Reading Level Gauges with armored shield, Sight Flow Indicators, Specific Gravity Analyzers, Point Level Switches, and other accessories based in Baton Rouge, Louisiana.

Known for reliable operation and maintenance-free performance, Jogler products are custom designed to fit customer specifications and manufactured per appropriate ASME B31.1 and B31.3 code standards. Jogler's manufacturing capabilities include CNC machining, modern equipment for extruding process connections, welding machines, water jet machines, glass lathe, and in-house powder paint capabilities. Additional in-house services include X-ray, PMI with and without carbon content, post-weld heat treatment, epoxy coating, and oxygen cleaning.

Jogler's modern production capabilities, together with internal quality systems, enable on-time delivery and short lead times for their customers.

For more information about Jogler Level Products in Arizona and New Mexico call 801-264-1114 or visit https://process-tech.com.

Pinch Control Valves for Regulating Flow of Slurries, Abrasives, Fibrous and Corrosive Media

Red Valve Control Valves offer maximum durability with precise control and virtually no maintenance. A heavy-duty pinch mechanism positions the sleeve for accurate control over a wide flow range.

Red Valve Control Pinch Valves have no packing to maintain or seats to wear, no fugitive emissions and no need for expensive body alloys. Variable orifice and cone sleeves can be specified to further enhance control performance and match the exact CV level desired. True feedback positioning is accomplished through the direct linkage of the pneumatic positioner to the valve stem shaft, with no splitting of the positioner output. Red Valve Control Products are available with pneumatic, electro-pneumatic, or digital positioners to link up to all control systems.

For more information contact Process Technology, Inc.

801-264-1114

https://process-tech.com

New Product Alert - The LowFlow MK708MAX Control Valve

Designed for high-pressure gas applications, aerospace/fuel testing, refining/chem/petrochemical, and pilot plants the new MK708MAX is a valuable addition to the Richards Industrials LowFlow brand of precision globe-style control valves, providing entry into higher flow applications.

DOWNLOAD THE MK708MAX DATASHEET HERE

MK708MAX Product Highlights

- Capable of handling 1,000psi (69 bar) inlet pressures at 100°F (38°C) - the competition only goes up to 720psi (50bar)

- CVs ranging from 6.5-10 (5.6 - 8.65kv)

- Body Material Options- Bronze, Carbon Steel, and Stainless.

- Available in 1” (DN25)

Siemens SITRANS store IQ Smart Monitoring Apps

Siemens provides customers the ability to take process measurements and remotely track the operation and health of instrumentation, regardless of whether they have a SCADA, PLC, or DCS system.

Siemens provides a wide range of process measurements and unprecedented monitoring of those products' health and efficiency by leveraging Siemens' flow, level, pressure, temperature, and weight measurement. In combination with Siemens Mindsphere, information can then be submitted to the cloud and used to provide real-time tracking of various properties, as well as real-time data retrieval from multiple remote locations for your user community, anywhere and at any time.

CLICK HERE TO LEARN MORE ABOUT SIEMENS SITRANS STORE IQ SMART MONITORING

Contact Process Technology, Inc. for more information. Call them at 801-264-1114 or visit their website at https://process-tech.com.

Steriflow FBCV Sanitary Control Valves - OR Version

The Steriflow FBCV O-Ring Series by Steriflow meets the rigid specifications for sanitary process control valves for customers who prefer an O-ring style stem seal. This valve series is suitable for various cosmetic, dairy, and food and beverage industries. Conforming to 3A guidelines, the FBCV is ideal for a wide range of flowing media in both the utility and process areas of sanitary systems.

In general, o-ring stem seals (what ASME BPE defines as sliding stem seals) for control valves on clean air and gas and liquid clean utility applications like USP Purified water and some CIP fluids. In contrast, diaphragm type control valves are on WFI (Water for Injection) systems for end of loop back pressure control, buffer dilution skids, and filtration skids for pressure and flow control and chromatography elution flow control.

The FBCV-OR's high rangeability, characterized trim, high capacities, superior temperature, and pressure ratings, and a selection of sealing methods make the sanitary control valve ideal for liquid, gas, and steam services. Whether the need is to control pressure, temperature, flow, pH, or another variable, the FBCV is the correct valve for your process.

DOWNLOAD THE FBCV-OR PRODUCT DATA SHEET HERE

PTI provides products used in various steam applications, including plant steam, filtered steam, clean steam, and pure steam. Products include back pressure regulators, pressure regulators, steam traps, check valves, butterfly valves, ball valves, and ancillary products.

PTI provides reliable and highly trusted sanitary and hygienic process products used by food, beverage, dairy, pharmaceutical, and life science industries.

Contact Process Technology, Inc. for more information. Call them at 801-264-1114 or visit their website at https://process-tech.com.

Process Technology, Inc. Combines Partner Technology and Delivers Innovative Industrial Effluent Wastewater Measurement Solution

Due to the regulatory nature, readings are taken multiple times a day manually, and constant alarms require a technician's attention. Questionable flow data and an ultrasonic level sensor that would not read below 3 GPM did not collect accurate or consistent flow data over the flume. pH buffers and calibrations were up to date, but due to the device's questionable age and occasional data dropout, it did not meet the regulatory requirements.

This application aims to regulate pH and flow and improve wastewater monitoring data collection's accuracy and efficiency, stay in compliance and ensure instrument reliability with a cost-efficient solution, reducing downtime.

The Mettler Toledo M300 with an iSense 3250i pH probe provides the most reliable and accurate pH capabilities in the industry, along with added digital monitoring. Calibrations are done on the bench in a controlled environment. The sensor will tell the transmitter the approximate life of the sensor, reducing system downtime.

The Siemens LU 240 for ultrasonic level (over existing flume) calculates flow and is a very cost-effective way to gather accurate levels. A single device with a local display and a 4-20mA output covers all communication bases and accuracy requirements.

A Red Lion 10” Graphite HMI consolidates data gathering and calculates flow using the existing cellular, returning data to the control room. Data is logged in the HMI via SD Card, so if there is an interruption in the system control room, no data is lost.

PTI's industrial water and wastewater customers’ monitoring challenges are addressed by combining the technology from (3) leading instrument and technology manufacturers.

Siemens, Mettler-Toledo, and Red Lion devices are compatible with providing a cost-effective and accurate automated flow monitoring solution, mitigating the risk involved with regulatory applications.

DOWNLOAD A HARD COPY OF THIS CASE STUDY HERE

Contact Process Technology, Inc. for more information. Call them at 801-264-1114 or visit their website at https://process-tech.com.

The SIEMENS SIPART PS100 Electro-pneumatic Positioner

/p>

The SIEMENS SIPART PS100 electro-pneumatic positioners control the valve or damper position of pneumatic linear or part-turn actuators. The SIPART PS100 electro-pneumatic positioners modulate the valve according to the setpoint value. A hallmark of the SIPART PS100 is its low consumption of air. Thanks to the piezoelectric technology, compressed air is only required to move the valve. In the steady-state, consumption of air is negligible.

SIPART PS100 FEATURES:

- Fast commissioning at the push of a button.

- Simple operation via the display and four buttons.

- Display symbols according to NAMUR NE 107.

- Negligible air consumption in stationary operation.

- Setting the application profile based on predefined selection options, e.g., tight-closing valve, open/close valve, small valve.

- Fast response in end positions ensures short positioning times and tight valves.

- Insensitive to vibrations and steam hammer.

- Leakage compensation ensures a constant actual value and protects the actuator.

- Only one device version for linear and part-turn actuators.

SIPART PS100 INDUSTRIES:

- Power stations

- Paper and glass

- Water and wastewater

- Food and pharmaceuticals

Process Technology, Inc. Delivers Automated Perlite Silo Level Measurement Solution

Objective

To increase measurement accuracy and reduce the risk of injury by eliminating the twice daily need to climb to the top of 60’ silos to measure the level of perlite.

Safely and accurately measuring the level of raw and processed perlite, a very dusty low dielectric mineral, is a daily requirement for our customer. With the assistance of our engineering team, the technology from (2) leading instrument and technology manufacturers were combined for a solution that can be applied at several perlite plants to address silo level monitoring challenges.

Challenge

Old and non-functioning cable fed level devices require an operator to take manual measurements twice a day from the top of (4) 60’ silos. This is a potentially dangerous measurement as the weather conditions could present a slip and fall, as well as the hazard and exposure to harsh elements.

The measurement data needs to be logged twice a day for inventory purposes and a local display for filling or drawing material is necessary for the drivers and operators.

Approach

Siemens SITRANS LR560 Radar Level Transmitter is a “Rockstar” in dusty tough solids level applications. The LR560 2-wire, 78 GHz FMCW radar level transmitter continuously monitors solids in the silos to a range of 100 m (328 ft). With plug and play performance, it is ideal for perlite applications, including those with extreme dust and high temperatures to +200 ºC (+392 ºF).Red Lion 10” Graphite HMI with analog I/O card and terminal strip for incoming power has preprogrammed HMI scaled to match radar scaling for dependable data logging and communication capabilities.

A Red Lion module is preprogrammed to (4) Siemens transmitters to provide level measurement for each silo, along with accurate data logged and displayed for operators and drivers.

Process Automation ROI

The largest gain in automating outdoor top of silo level measurements with reliable products is eliminating the need to climb to the top of the silos twice a day to retrieve a level measurement. This process allows for constant and accurate silo monitoring with a significant reduction in risk of injury and optimizes work time.

Siemens and Red Lion devices are compatible to provide a cost-effective and accurate automated silo level measurement solution, mitigating the risk involved with a twice daily task.

DOWNLOAD A HARD COPY OF THIS CASE STUDY HERE

Contact Process Technology, Inc. for more information. Call them at 801-264-1114 or visit their website at https://process-tech.com.