The Process Technology Blog provides educational and product information for the industrial process control and factory automation markets. Posts will include application information, new product announcements, How-To's, and process control education. This blog is sponsored by Process Technology, Inc. Contact PTI by calling 801-264-1114 or visiting their website at https://process-tech.com.

Siemens Level Measurement Selection Guide

Complete level solutions from Siemens and Process Technology, your trusted partners.

Simply put, level measurement tells you how much material is at a given location. Because no single technology measures level in all applications, Siemens and PTI offer selection. Monitoring water levels in open channels, tracking the amount of grain in a silo, measuring oil in a tank. Siemens level measurement instruments let you get on with your day. Easy 4-button programming and graphical Quick Start Wizards deliver headache-free installation and setup. Advanced processing means that operators aren't spending valuable time troubleshooting devices. Instead, they can be confident that these instruments are providing reliable, accurate results. Complementing Siemens level technology is Siemens' complete suite of process instruments.

Download the Siemens Level Measurement Selection Guide Here

Contact Process Technology, Inc. for more information. Call them at 801-264-1114 or visit their website at https://process-tech.com.

COVID-19 Testing in School and University Wastewater Systems

Community spread of COVID-19 is challenging to control because symptoms can take up to two weeks to appear after contracting the virus. Making this even more challenging is the fact that many cases remain asymptomatic. As a complement to existing testing processes, communities, including universities, are searching for a more proactive approach to identifying early infection trends.

One of the most exciting advances in Wastewater-based epidemiology (WBE) is the recently demonstrated ability to identify and measure COVID-19 genetic material in untreated wastewater reliably. SARS-CoV-2, which is the virus that causes Covid-19 and is known to invade the gastrointestinal tract and is extracted in human sold waste.

The broad descriptions for various testing methodologies used to measure municipal water quality are "wastewater testing" or "wastewater quality indicators." These testing methods analyze wastewater's physical, chemical, and biological characteristics and now include testing for SARS-CoV-2. By sampling and testing wastewater samples, COVID-19 outbreaks are predictable well in advance.

To arrest Coronavirus's spread on campuses, schools and universities are turning to wastewater testing as a possible method for identifying and predicting outbreaks of Covid-19 in their facilities. Evidence is still preliminary, but it appears promising that this approach can allow schools to detect potential flareups weeks earlier than conventional population monitoring. Schools using wastewater-based epidemiology detection methods find COVID-19 more efficiently and less invasively compared to blanket individual student testing. The knowledge of increasing COVID-19 genetic material in untreated wastewater by schools and universities allows more precise deployment of mitigation initiatives and response plans, such as testing individuals, contact tracing, and quarantine.

HACH, a world-leader in water quality instrumentation and analysis, provides portable samplers that help researchers identify hot spots. The portable analyzer takes daily samples to determine the presence of SARS-CoV-2, assisting researchers in predicting COVID-19 outbreaks.

To learn more about testing wastewater for COVID-19, contact Process Technologies, Inc. Call them at 801-264-1114 or visit their website at https://process-tech.com.

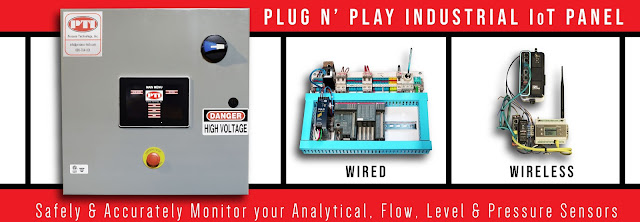

Industrial IoT Panel Solution - Safely and Accurately Monitor Your Analytical, Flow, Level or Pressure Sensors

Process Technology, Inc. is pleased to introduce their Industrial IoT Panel Solution, a control panel series designed to improve operational efficiency and lower costs by monitoring compressors, generators, tank levels, pressure, temperature, and vibration on a wireless or wired panel.

The IoT Panel Solution provides Plug n Play control options customized for your application. PTI sales engineers discuss your requirements on-site, evaluate, design, and implement a complete cost-efficient solution kit to automate your process and factory automation application.

Wired Panel Components

- Red Lion HMI

- 10-amp power supply

- Ethernet Switch

- Universal input card

- Programming

Wireless Panel Components

- Red Lion HMI

- 10-amp power supply

- Ethernet Switch

- Wireless Gateway plus two nodes

- Programming

Standard panel sizes:

- 24" x24" x10"

- 20" x20" x10"

- 13" x14" x9"

Options included:

- I/O link

- Data tracking

- PLC

- Wireless communications

- Additional options available

Calibrating a Mettler Toledo InPro 3250 pH Sensor Connected to an M400

The Mettler Toledo Process Analytics InPro 3250 is a pre-pressurized liquid-electrolyte pH probe with temperature sensor. The InPro 3250 are designed for an extensive range of applications in the biotechnology, pharmaceutical and chemical process industries.

The Mettler Toledo M400 is a 4-wire transmitter with multi-parameter and ISM capabilities.

This video demonstrates the process of calibrating an analog InPro 3250 pH sensor connected to an M400 transmitter.

Contact Process Technology for all your Mettler Toledo Process Analytics products. Call them at 801-264-1114 or visit them at https://process-tech.com.

Reliable Weighing Systems in the Harshest Industrial Environments

From the rigors of heavy industry to the precision required in food and pharmaceutical manufacturing, Siemens has weighed it all.

SIEMENS isn’t new to the weighing game. SIEMENS delivers over 50 years of experience in the weighing technology for continuous or static weighing and batching applications to optimize your process costs and quality. With SIEMENS field-proven SIWAREX weighing electronics, SIWAREX load cells, conveyor belt scales, solids flow meters and weighfeeders, SIEMENS weighs your world - with first-class solutions that help you accomplish almost any weighing task.

- Process weighing and gravimetric level measurement

- Dosing/Filling/Bagging scale

- Continuous Weighing

- Force/Torque measurement

DOWNLOAD THE SIEMENS DYNAMIC AND STATIC WEIGHING INSTRUMENTATION CATALOG HERE

For more information about SIEMENS process weighing products, contact Process Technology. Call them at 801-264-1114 or visit them at https://process-tech.com.

New Product Alert: AbTech Industries

Process Technology is pleased to announce a partnership with AbTech Industries.

AbTech Industries is a full-service environmental technology and engineering company committed to offering creative solutions to cities, business and governments solving water pollution and contamination issues.

Offering revolutionary solutions for Stormwater Management, Oil & Gas Water Treatment and Industrial Waste Water Treatment, AbTech combines its own proprietary technology with third-party technologies and systems to provide customers with the most reliable and cost-effective solutions.

Process Technology offers AbTech products in Utah, Western Wyoming, Southern Idaho, Northern Nevada, Arizona, New Mexico, Colorado, Eastern Wyoming, and Montana.

AbTech Industries Products Include:

- Stormwater treatment - Engineered systems, storm drain inserts, environmental site solutions focused on reducing coliform bacteria, hydrocarbons, TSS, nutrients & heavy metals

- Oil & Gas water management - Upstream, midstream & downstream water management solutions

- Industrial water treatment - filtration media solutions, water treatment systems.

For more information on AbTech products, contact Process Technology by calling 801-264-1114, or using visiting their website at https://process-tech.com.

SIEMENS Flow Measurement Product Guide

The right flow instrument for every application.

SIEMENS flow instrumentation allows you to measure the flow of liquids, gas and steam with greater confidence. From simple flow indicators to advanced bus-compatible electronic systems, the trusted SITRANS F product family has versatile and reliable metering solutions built to suit every industry and process.With the knowledge that no single technology can address the needs of all industrial applications, SIEMENS provides a complete range of flow measurement devices. And all are backed by our global support network, providing experienced sales and technical assistance when and where you need it.

GET THE FLOW MEASUREMENT GUIDE FROM THIS PTI WEB PAGE

For more information about SIEMENS Process Instrumentation products, contact Process Technology. Call them at 801-264-1114 or visit their website at https://process-tech.com.

Happy Labor Day from Process Technology!

A sincere thanks from PTI to all the hard working people that make the US economy run each and every day.

Crimson Configuration Software by Red Lion: Protocol Conversion

Crimson, by Red Lion, is a powerful set of drag-and-drop configuration, display, control and data logging tools, Crimson works with Red Lion's industrial automation products, including CR1000, CR3000 HMIs, Graphite® HMIs and Graphite Controllers, and E3 I/O™ modules.

Crimson features support for over 300 protocol drivers, including Modbus RTU and TCP/IP, EtherNet/IP, Emerson ROC, and both DNP3 serial and Ethernet communications. With an intuitive, drag-and-drop graphical user interface and a variety of hardware offerings each supporting multiple simultaneous conversions, customers can easily integrate new functionality into virtually any PLC, PC or SCADA system.

With Crimson, simple applications can be set up quickly using a step-by-step process to configure communications protocols and define data tags for access. An extensive menu of built-in, point-and-click serial and Ethernet drivers map controller data to PLC registers in seconds. Built-in communications drivers inherently know how to talk to PLCs, PCs or SCADA systems — so no code is required to establish communication.

For more information about Red Lion products, contact Process Technology. Call them at 801-264-1114 of visit their website at https://process-tech.com.

The MSA ULTIMA® X5000 Gas Monitor

The ULTIMA® X5000 Gas Monitor is the future of gas detection for oxygen, toxic and combustible gases. MSA XCell® gas sensors with TruCal® technology offer calibration cycles up to 18 months (local calibration respected). The gas transmitter's advanced, multi-lingual OLED display is easy to read and the unique touch-screen interface makes it simple to navigate.

The ULTIMA® X5000 Gas Monitor Features:

- Bluetooth wireless technology

- Check status and get alerts up to 75 ft. (23 m) away

- Modify settings/setpoints/alarms

- Initiate calibration and view progress

- Reduce setup time by at least 50%

- Up to 1.5 YEARS between calibrations!

- Adaptive Environmental Compensation (AEC)

- 12+ Patents

- 5 Yr. Expected Life

- 3 Yr. Warranty

DOWNLOAD THE ULTIMA® X5000 BROCHURE HERE

For more information on the ULTIMA® X5000, contact Process Technology, Inc. Call them at 801-264-1114 or visit https://process-tech.com.

Pretreatment Sewage Testing and Monitoring Gaining Favor as Coronavirus Outbreak Predictor

Wastewater testing, or “wastewater quality indicators” are broad descriptions for the various test methodologies to measure water quality. These tests analyze the physical, chemical, and biological characteristics of wastewater.

As countries and individual healthcare organizations work to arrest the spread of Covid-19 and to care for those who are infected, officials in some geographic locations are using wastewater testing as a possible method for identifying levels of Covid-19 in their communities. The testing goal is to detect evidence of the Covid-19 genetic material, ribonucleic acid (RNA), in fecal matter in sewage and wastewater.

The novel virus, SARS-CoV-2, is the virus that causes Covid-19. It is known to invade the GI (gastrointestinal) track in some patients, and so the virus is extracted in their fecal matter.

Looking at the amount of viral matter in waste water from a community could uncover the level of Covid-19 spread in the population. This information can then be a trigger for the required mitigation initiatives and response plans, such as testing individuals, contract tracking, and quarantine. It also allows for information to be gathered on a cross section of the population, allowing for a way to monitor public health solutions for large groups.

Scientists from around the world are setting up pilot programs to test waste water. The Netherlands has successfully performed a Covid-19 test for waste water and additional programs are launching in Singapore, Zurich, Lausanne, Milan, Rome, Australia, and in parts of the US, such as Colorado, Ohio, New York, and Wyoming. Scientists in these regions have been able to identify the novel Coronavirus at low concentrations in waste water, pointing to an early warning systems for communities.

In April, 2020, the scientific journal, Nature, listed that over a dozen groups around the globe were doing research analyzing waste water for Covid-19, and that evidence of the virus was already found in the United States, the Netherlands, and Sweden.

|

| Figure 1 |

A valuable tool in pre-treated water analysis are Automatic Samplers. These devices automate the collection of sewage samples and prepare them for further analysis to ascertain the existence and amount of virus in the wastewater sample.

For more information about automatic samplers contact Process Technology. Call them at 801-264-1114 or visit their website at https://process-tech.com.

Jordan Valve's Sliding Gate Seat Technology for Regulators and Control Valves

- Straight Thru Flow – The control element is perpendicular to the flow, resulting in less turbulence and superior trim life.

- Constant Contact in Seats – The disc and plate are in constant contact. Therefore, there is no valve ‘chatter’, less mechanical wear and greater stability at the low end of the stroke. The constant contact results in a self-lapping and self-cleaning action. Jordan Valve sliding gate seats wear in – they don’t wear out.

- Easy Maintenance – There is only one moving part in the Sliding Gate Seats. The seats are not pressed or screwed into place, so removal is easy. Cv values are interchangeable and control valve action is easily changeable.

- Short Stroke – In regulators, this results in faster response to input signals, less droop (greater accuracy), and longer diaphragm life. In control valves, the short stroke of the sliding gate seat results in less packing wear. Additionally, smaller actuators can be used resulting in lighter weight, smaller envelope dimensions and less air consumption.

- Seat Materials – Jorcote is the standard seat material. Jorcote is harder than stainless steel and provides excellent wear, erosion, & galling resistance. It has a lower coefficient of friction than Teflon; providing higher pressure drop capability and less offset. Jorcote seats perform in temperatures from sub-zero to 550°F (288°C). These seats have been lab tested to 1,000,000 full stroke cycles in 70 psi steam and maintained ANSI Class IV leakage while displaying negligible wear.

- Disc Plate Overlap – The disc and plate overlap by 1/32” (0,8mm) around each orifice. This creates an area of closure, not line of closure, resulting in better shutoff for a longer period of time, reducing waste and lowering costs.

- Multiple Orifice Design – The multiple orifice design of the sliding gate seat dissipates the wear energy and downstream flow, resulting in longer trim life and quiet operation.

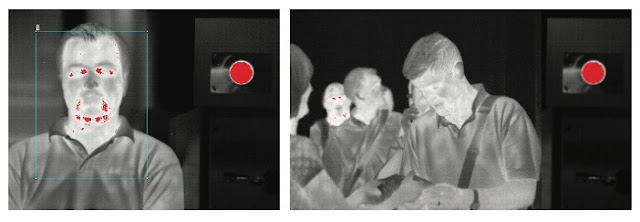

New Product Update: AMETEK Land Instrument vIRalert 3 - Human Body Temperature Screening System

AMETEK Land Instrument has updated their vIRalert 2 human body temperature screening system to the all new vIRalert 3, an economical way to monitor the wellness of each of your employees, visitors, contractors and vendors entering your facility. The VIRALERT 3 is a real-time scanning solution that’s safe, accurate, and easy to use.

Siemens Process Instrumentation Start-up, Commissioning Services, and Maintenance

Are you concerned about future service and support when making a large process instrument investment? Do you want to make sure you're in the right hands and that the partner you choose will be there when you need them?

Process Technology, Inc. (PTI) is an authorized SIEMENS instrumentation sales and service representative with highly-skilled support staff and trained engineers providing start-up services on any new Siemens process instruments as well as on-going support for equipment installed in the field.

PTI INSTRUMENTATION SERVICES

Start-up and Commissioning Services

Safe start-up provides reliable operation of equipment and processes to increase safety, minimize downtime and enhance productivity.- Technical assistance during installation and startup

- Initial testing of equipment

Calibration Services

Assure that all systems and components of equipment and processes optimize their operationMagnetic Flowmeter Verification

- Test to ensure that the set standard is accurate

- Documentation and training

Preventative Maintenance Services

Continue engineering services or portfolio repair to maintain equipment and system integrity.- Monthly

- Quarterly

- Yearly

Process Instrumentation Operator and Technician Training

PTI tailors our process to meet your specific needs and schedule.- In-house and on-site training programs

- Pressure, temperature, level, valve positioners, loop controllers, flow and weighing.

Technical Demand Services

Support your unplanned service needs or troubleshooting support for instrumentation and analyzers.For more information, contact Process Technology, Inc. Call them at 801-264-1114 or visit their website at https://process-tech.com.

New Sierra Instruments Product Catalog

Process Technology, Inc.

https://process-tech.com

801-264-1114

Safe Work Solutions During COVID-19 from Banner Engineering and Process Technology

Companies around the world are quickly adapting to the many challenges posed by the COVID-19 pandemic. The need is immediate. Banner Engineering and Process Technology are ready to help.

Process Technology draws on Banner's large catalog of automation products to create solutions that solve real problems. These solutions are designed to be easy to implement, built to perform reliably in challenging environments, and continually adapt to meet changing requirements and needs.

Safe work solutions help companies meet and overcome the challenges they face today so they can more effectively serve and support their customers, employees, and communities while they plan for the future.

For more information, contact Process Technology now. Call them at 801-264-1114 or get more information about Safe Work Solutions for COVID-19 here.

Reduce COVID-19 Spread and Fear by Screening for Fever with this Automated System

What precautions do you have to currently take to monitor the health of the people who access your facility in order to feel confident that your facility is clean and virus free?

An economical way to give peace of mind to your staff showing you are invested in protecting them and your facility is a system that will help you monitor the wellness of each of your employees, visitors, contractors and vendors entering your facility.

AMETEK Land is a world leading manufacturer of precision temperature measuring equipment, specializing in non-contact temperature measurement. Their vIRalert 2 fixed thermal imaging system provides remote measurement of human body temperature (typically the face) to an accuracy of within 0.9 degree F (0.5 deg. C) allowing the detection of the small changes in temperature induced by a fever.

The vIRalert 2 system can provide accurate and reliable skin temperature measurement for the mass screening of high pedestrian areas like airports, train stations, key operational facilities and factories and other places where infectious diseases can easily spread.

KEY APPLICATIONS

- TRANSPORT AND TRAVEL - Airports, Railway Stations, Subways, Underground Rail Systems, Large Public Buildings.

- EDUCATION - Schools, Colleges, Universities, Municipal Libraries.

- BUSINESS - Manufacturing Facilities, Warehouses, Offices, Government Buildings.

The AmetekLand vIRalert 2 body temperature measurement system is installed at any access point in your facility, once installed the system will take an instant non-intrusive body temperature measurement, without slowing the flow of foot traffic, and give a visual and audible alarm for alert allowing you to take the necessary steps to protect your facility.

The AmetekLand vIRalert 2 body temperature measurement system is installed at any access point in your facility, once installed the system will take an instant non-intrusive body temperature measurement, without slowing the flow of foot traffic, and give a visual and audible alarm for alert allowing you to take the necessary steps to protect your facility.- Entrances

- Shipping & Receiving

- Factory Floor

- Conference Rooms

- Security Gate

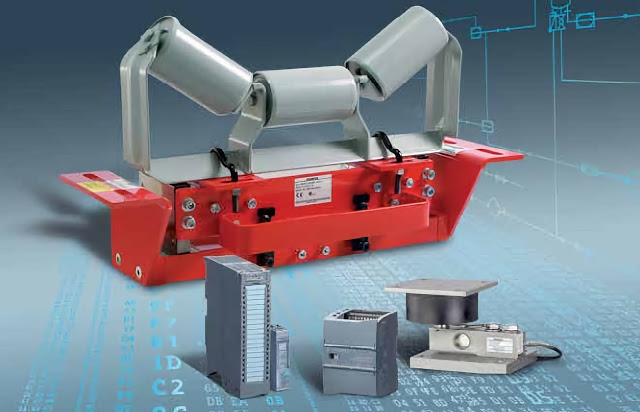

Installation of the Siemens Milltronics MSI Belt Scale

The Siemens Milltronics MSI is a heavy-duty, high-accuracy, full-frame single idler belt scale used for process and load-out control in a variety of industries including mines, quarries, power generation, iron, steel, food processing and chemicals. The MSI’s patented use of parallelogram-style load cells results in fast reaction to vertical forces, ensuring instant response to product loading and providing outstanding accuracy and repeatability even with uneven loading and fast belt speeds. The MSI is installed in a simple drop-in operation and may be secured with just four bolts. An existing idler is then attached to the MSI dynamic beam. With no moving parts, maintenance is kept to a minimum, with just periodic calibration checks required.

For more information about Siemens products, contact Process Technology, Inc. Visit their web site at https://process-tech.com or call them at 801-264-1114.

Safety Light Curtains to Prevent Injury and Equipment Damage

The Tideflex Technologies CheckMate® UltraFlex™ Inline Check Valve

The Tideflex Technologies CheckMate® UltraFlex™ Inline Check Valve is the valve of choice for municipal applications such as stormwater, wastewater, highway run-off, CSO, SSO and flood control. It is the most user friendly inline check valve on the market today. From the upstream or downstream end of the pipe, simply insert the valve into position and clamp it into place. Typically no modification to the pipe or structure is required. CheckMate® UltraFlex™ Valves have become the specified solution for residential and commercial areas where complete, dependable backflow prevention is necessary to prevent surcharging and flooding.

For more information, contact Process Technology, Inc. Call them at 801-264-1114 or visit their web site at https://process-tech.com.

Process Technology, Inc. Expands Banner Engineering Coverage into Colorado, Montana and Wyoming

Process Technology, Inc. (PTI) has expanded its presence into Colorado, Montana and Wyoming by representing Banner Engineering. For over 30 years, PTI‘s expertise has identified and solved some of the toughest automation challenges in industry throughout the Rocky Mountain region.

“Our Front Range team will offer large and small companies the opportunity to strengthen their automated processes with the quality and excellence of Banner’s IIOT and Smart Factory solutions,” says PTI CEO Chris Wheat. “We are ready to provide the Colorado, Montana and Wyoming territories the benefits of Banner Engineering’s well-built products, innovative processes and customer service.”

PTI has an established team in the Front Range. Sales Engineers, Aaron Mooney, Rich Robins, Steve Pitkin, Buddy Alford and Applications Engineer, Brian Waslo have the industry knowledge that have enabled our customers to achieve their automation goals. Based in the PTI Denver office, Brian states, “With the addition of Banner’s products and custom solutions, we have an opportunity to satisfy our customer’s requirements by analyzing all the necessary elements of an application and identifying the essential products, features and components to increase productivity.”

The PTI territory expansion of Banner Engineering products, specializing in sensors and vision sensors, LED lights and indicators, wireless and safety products - will give customers in the Colorado, Montana and Wyoming territories a broad selection of superior quality products to solve application challenges. The Front Range Sales and Support team, the “Experts at the Heart of Industry” will configure, quote and order Banner products with reliability and outstanding customer service.

About Process Technology, Inc. (PTI)

Process Technology, Inc., located in Salt Lake City, Utah, has been solving process control and factory automation challenges since 1986. With branch offices located in Arizona and Colorado, serving industrial B2B customers in Utah, Wyoming, Southern Idaho, Northern Nevada, Arizona, New Mexico, Colorado, and Montana.The PTI Team are factory trained, experienced professionals that are experts in process control and factory automation. The “PTI People” have a deep commitment and dedication to customers and vendors.

Process Technology, Inc. Expands Turck USA Coverage into Colorado, Montana and Wyoming

Process Technology, Inc (PTI), along with Turck USA, announces an expansion of territory to include Colorado, Montana and Wyoming.

Process Technology, Inc (PTI), along with Turck USA, announces an expansion of territory to include Colorado, Montana and Wyoming.Process Technology, Inc. (PTI) has expanded its presence into Colorado, Montana and Wyoming by representing Turck USA. For over 30 years, PTI ‘s expertise has identified and solved some of the toughest challenges in industry throughout the Rocky Mountain region. “Our Front Range team will offer industry of all sizes the opportunity to strengthen their automated processes with the durability, functionality, and performance of Turck’s distributed I/O and connectivity solutions,”says PTI CEO Chris Wheat. “We are ready to provide the Colorado, Montana and Wyoming territories the most up-to-date processes and customer service that Turck USA products bring.”

PTI has an established team in the Front Range. Sales Engineers, Aaron Mooney, Rich Robins, Steve Pitkin, Buddy Alford and Applications Engineer, Brian Waslo have the technical industry expertise that have enabled our customers to prosper. Based in the PTI Denver office, Brian states, “With the addition of Turck’s products and solutions, we have an opportunity to pair industry-specific knowledge with custom electronics development, guaranteeing optimal solutions for automation challenges.”

The PTI territory expansion of Turck products, specializing in high quality sensors, fieldbus, and connectivity - as well as interface technology and RFID systems will give customers in the Colorado, Montana and Wyoming territories cost efficient, effective solutions across industries. The Front Range Sales and Support team, the “Experts at the Heart of Industry” will configure, quote and order Turck products with reliability and outstanding customer service.

Contact Process Technology by calling 801-264-1114 or by visiting their web site at https://process-tech.com.