The Process Technology Blog provides educational and product information for the industrial process control and factory automation markets. Posts will include application information, new product announcements, How-To's, and process control education. This blog is sponsored by Process Technology, Inc. Contact PTI by calling 801-264-1114 or visiting their website at https://process-tech.com.

Season's Greetings and Happy New Year from Process Technology

Thermal Mass Flowmeters: Advancing Efficiency in Industrial Applications

Understanding Thermal Mass Flowmeters

Performance and Advantages

Common Applications

EPI Thermal Flowmeters: The FAT Probe Advantage

801-264-1114

Enhancing Safety and Hydrogen Purity in Water Electrolysis with Advanced Gas and Moisture Analyzers

Download Panametrics' white paper titled "Ensuring Process Safety and Product Quality in Water Electrolysis Using Oxygen, Hydrogen, and Moisture Analyzers" to learn how advanced analyzers enhance safety and ensure hydrogen purity in water electrolysis processes.

Red Lion Rolls Out High-Performance RTUs for Demanding Industrial Applications

801-264-1114

Precision and Purity: The Advanced Fluid Process Pumps from SMC

https://process-tech.com

801-264-1114

Mining Slurry Valve Application: Optimizing Efficiency, Reliability, and Service Life

Abrasion is one of the most challenging issues for valves when used in mining industry slurries. Slurries often contain abrasive particles, such as sand, gravel, and rock fragments, which can cause significant wear and tear on valve components. Over time, this abrasion can lead to valve failures, leaks, and reduced performance, resulting in costly downtime and maintenance.

To manage the challenge of abrasion, valve manufacturers employ several strategies:

Material selection: Valve components exposed to abrasive slurries are constructed from highly wear-resistant materials, such as hardened alloys, ceramics, or elastomers. These materials can withstand the constant bombardment of abrasive particles and maintain their integrity over extended periods.

Coating and surface treatments: Valve surfaces can be coated with hard-wearing materials, such as tungsten carbide or chrome, to increase their resistance to abrasion. These coatings provide an extra layer of protection and can significantly extend the valve's service life.

Design modifications: Valve designs can be optimized to minimize the impact of abrasive slurries. For example, some valves feature streamlined flow paths that reduce turbulence and minimize the contact between the slurry and valve components. Other designs incorporate replaceable wear parts, such as sleeves or liners, which can be easily replaced when worn without replacing the entire valve.

Proper sizing and selection: It is crucial to select the right valve size and type for the specific slurry application. Oversized valves can increase turbulence and accelerate wear, while undersized valves can cause high-pressure drops and reduced performance. Valve experts can help mining companies select the most suitable valve for their specific slurry application, considering particle size, concentration, and flow rate.

Regular maintenance and monitoring: Implementing a regular maintenance and monitoring program can help detect and address abrasion issues before they lead to valve failures. Regular maintenance may include periodic inspections, cleaning, and replacement of worn components and monitoring of valve performance indicators, such as pressure drop or leakage rates.

Elastomer pinch valves, like those manufactured by Red Valve, are an excellent choice for mining slurry applications due to several key advantages they offer:

Abrasion resistance: Pinch valves feature a resilient elastomer sleeve that can withstand the abrasive nature of slurries. The elastomer material, such as natural rubber or neoprene, can absorb the impact of abrasive particles and resist wear, ensuring a long service life even in challenging mining conditions.

Full-bore design: Pinch valves have a full-bore design, meaning that when fully open, the valve's internal diameter matches the pipeline's diameter. This design minimizes flow restrictions, reduces turbulence, and lowers the risk of clogging or material buildup, which is particularly important in slurry applications.

Gentle handling of materials: The elastomer sleeve in pinch valves gently compresses the slurry, minimizing the shear forces and particle degradation that can occur with other valve types. This gentle handling helps maintain the slurry's consistency and reduces the risk of valve damage caused by sharp or oversized particles.

Simple design and easy maintenance: Pinch valves have a simple yet effective design with few moving parts. This simplicity makes them easy to install, operate, and maintain. The elastomer sleeve is the only component that comes in contact with the slurry, and it is easy to replace when worn without removing the valve body from the pipeline.

Tight sealing: When closed, the elastomer sleeve provides a tight, 360-degree seal, preventing leaks and ensuring reliable shut-off. This tight sealing is crucial in mining applications, where leaks can lead to material loss, environmental concerns, and safety hazards.

Versatility: Pinch valves can handle various slurry consistencies, from thin, watery mixtures to thick, paste-like materials. They can also operate in multiple flow control modes, including on/off, throttling, and even non-slam check valves, providing flexibility in mining process control.

Corrosion resistance: The elastomer sleeve in pinch valves resists abrasion and provides excellent corrosion resistance. This is particularly important in mining applications, where slurries may contain corrosive chemicals or have extreme pH levels that can damage other valve types.

Red Valve, a leading manufacturer of pinch valves, offers a range of valves designed explicitly for mining slurry applications. Their valves withstand the most challenging mining conditions, providing reliable performance and long service life. By choosing elastomer pinch valves from reputable manufacturers like Red Valve, mining operations can benefit from improved process efficiency, reduced maintenance costs, and increased overall system reliability.

And as always, collaboration between mining companies and local valve experts is essential to develop and implement the most effective solutions for each application.

Process Technology, Inc.

https://process-tech.com

801-264-1114

Enhancing Craft Beer Quality with High-Quality Measurement Solutions

1. pH Measurement:

pH plays a crucial role in the brewing process, as it affects enzyme activity, yeast health, and the overall flavor and stability of the final product. Accurate pH measurement is essential during mashing, as the optimal pH range (5.2-5.6) ensures efficient starch conversion and extraction of fermentable sugars. During fermentation, yeast activity can cause pH shifts, which need monitoring to prevent off-flavors and ensure consistent fermentation. High-quality pH meters with automatic temperature compensation and calibration capabilities help brewers maintain tight control over pH levels, resulting in better product consistency and quality.

2. Dissolved Oxygen (DO) Measurement:

Oxygen plays a vital role in yeast health and fermentation, but excessive oxygen exposure can lead to oxidation and the development of stale, cardboard-like flavors in the finished beer. Measuring dissolved oxygen levels at various stages of the brewing process, particularly before and after fermentation, helps brewers ensure that their beer is not over-exposed to oxygen. High-quality DO meters with fast response times and minimal drift provide accurate and reliable measurements, allowing brewers to make informed decisions about oxygen management and prevent oxidation-related quality issues.

3. Dissolved CO2 Measurement:

Dissolved carbon dioxide (CO2) is responsible for beer's carbonation and mouthfeel. Accurate measurement of dissolved CO2 helps brewers achieve the desired level of carbonation for each beer style and maintain consistency across batches. High-quality dissolved CO2 meters with automatic pressure and temperature compensation provide precise measurements, enabling brewers to fine-tune their carbonation levels and ensure that their beers balance bubbles and creaminess.

4. Gaseous Oxygen Measurement:

In addition to dissolved oxygen, monitoring gaseous oxygen levels in the headspace of fermentation tanks and packaging lines is critical for preventing oxidation and ensuring beer quality. High-quality gaseous oxygen analyzers with low detection limits and fast response times allow brewers to quickly identify and address any oxygen ingress issues, minimizing the risk of oxidation and preserving their beers' freshness and flavor stability.

5. Conductivity Measurement:

Conductivity measures the total dissolved solids in water, which can impact beer's flavor, mouthfeel, and stability. Monitoring conductivity during brewing helps brewers ensure that their water chemistry is consistent and appropriate for each beer style. High-quality conductivity meters with automatic temperature compensation and wide measurement ranges provide accurate and reliable measurements, enabling brewers to decide about water treatment and ingredient additions.

6. Turbidity Measurement:

Turbidity, or beer's cloudiness, is an essential quality parameter that affects the final product's appearance and perceived quality. While some beer styles, such as hefeweizens, are intentionally cloudy, most beers are clear and haze-free. High-quality turbidity meters with low detection limits and good repeatability allow brewers to monitor the clarity of their beers throughout the brewing process and make necessary adjustments to ensure that their beers meet customer expectations for appearance and quality.

Investing in high-quality instruments for pH, dissolved oxygen, dissolved CO2, gaseous oxygen, conductivity, and turbidity measurements is crucial for craft breweries seeking to produce consistently high-quality beers. By accurately monitoring and controlling these critical parameters, brewers can optimize their processes, prevent quality issues, and deliver exceptional beer experiences to their customers. As the craft brewing industry continues to grow and evolve, those breweries that prioritize quality and invest in reliable measurement solutions will be well-positioned to succeed in an increasingly competitive market.

Process Technology, Inc.https://process-tech.com

801-264-1114

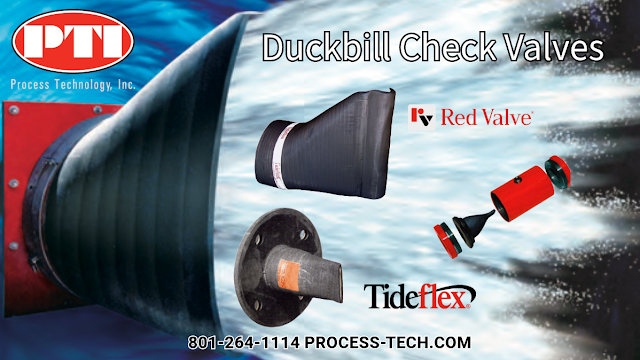

Duckbill Check Valves

Duckbill check valves allow flow in only one direction through a pipe or tube while preventing any backflow in the opposite direction. When fluid pressure is applied from the upstream side, the duckbill flexes open to allow flow. But if pressure comes from the downstream side, the duckbill flaps seal shut to block reverse flow.

Typical applications for duckbill check valves include:

- Preventing sewer and septic tank backflow

- Inline pump protection

- Sprinkler and irrigation systems

- Drainage and flood control

Duckbill valves' simple, passive operation offers reliable backflow prevention without needing manual intervention, a power source, or maintenance. The elastomeric duckbill is the only moving part. Its flexing action allows it to seal around solids, making it resistant to clogging compared to other check valve designs with hinge mechanisms that can jam.

Duckbill valves find wide use across industrial, municipal, and commercial sectors due to their simple and reliable operation, compact size, and low cost compared to mechanical check valves. Some of the most common applications include:

- Wastewater and stormwater management: Duckbill valves are extensively used in sewer lines, septic systems, and stormwater outfalls to prevent backflow of contaminated water during heavy rains or floods. They are less prone to clogging than flap valves.

- Irrigation and agriculture: In sprinkler systems and agricultural pipelines, duckbill valves maintain consistent flow direction and prevent pump prime loss. They also inhibit dirt, rodents, or other foreign materials from entering pipes.

- Marine and aquatic systems: Duckbill valves are used in boat bilge pump discharge lines, live fish holding tanks, and pond aeration systems. Their unobtrusive profile minimizes flow restrictions.

- Industrial processes: In chemical processing, printing, and manufacturing operations, duckbill valves control gases and liquids, vent tanks and pipelines, and isolate pressure gauges and instruments.

Compared to traditional swing check valves or spring-loaded poppet valves, duckbill valves offer several advantages:

- No mechanical hinge or spring to fail or wear out, giving them superior reliability and service life.

- Low cracking pressure and high flow rate due to streamlined design.

- Tight sealing even around suspended solids and minimal leakage.

- A simple one-piece elastomer duckbill is inexpensive to manufacture and easy to replace.

- Various elastomer choices to suit corrosive chemicals, high temperatures, or food grade needs.

Duckbill check valves' versatility, dependability, and low maintenance requirements make them a popular choice across diverse industries for providing economical, trouble-free backflow prevention and fluid control. While not suited for every application, they offer an elegant solution in many common fluid handling scenarios.

https://process-tech.com

801-264-1114

Siemens and Partners Launch Industrial Metaverse at CES 2024: Transforming Manufacturing and Infrastructure

https://process-tech.com

801-264-1114