The Process Technology Blog provides educational and product information for the industrial process control and factory automation markets. Posts will include application information, new product announcements, How-To's, and process control education. This blog is sponsored by Process Technology, Inc. Contact PTI by calling 801-264-1114 or visiting their website at https://process-tech.com.

Siemens Level Instrumentation

Vibration Analysis and Wireless Vibration Solutions from Banner

Introduction: What is Vibration Analysis?

Vibration analysis studies vibration's frequency, amplitude, and damping in mechanical structures to detect and diagnose faults in machinery and industrial equipment. Vibration analysis aims to identify the source of a potential or existing problem and provide a solution to fix it.

What are the Different Types of Industrial Vibrations?

Industrial vibrations are a common occurrence in many industries. They cause damage to equipment, structures, and even people if not controlled. It's critical to understand different industrial vibrations and how to manage them and minimize their effect on people and equipment.

The different types of industrial vibrations are:

- Shock Vibration - This is when an object is suddenly moved or released, causing it to move rapidly back and forth.

- Random Vibration - An object moves randomly with no pattern or specific frequency.

- Steady State Vibration - Steady-state vibration occurs when an object moves at a constant rate with no change in amplitude or frequency.

- Random Excitation - This vibration occurs when something vibrates because it has been disturbed by some external force such as noise or wind.

- Resonance

Industrial IoT Control Panel Design

Introduction: What is IIoT and Why is it Important?

Wireless Networking for Connected Devices

Control Panel Design for IIoT Systems

- Solve issues with costs and difficulties in traditional hard-wiring.

- Quickly and locally identify process conditions and alert, alarm, or correct outputs to normalize the process.

- Efficiently deploy various instruments and controls to interact with the process.

- Provide easy-to-understand displays showing in-depth information.

- Provide real-time information to corporate information systems.

- Are easy to install anywhere, even in remote locations with no power supply.

- Are more flexible with their use and have applications in many industry types.

Discuss Your IoT Control Application with Process Technology, Inc.

SITRANS P Pressure Instrumentation by Siemens

Process Refractometers for Petrochemicals and Oil & Gas Refining

The Equilibar® Flow Control Valve

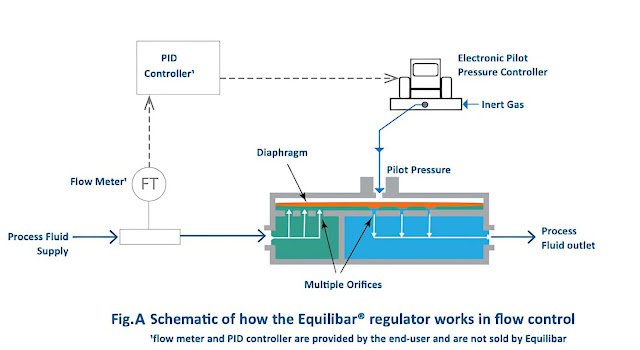

The Equilibar® flow control valve links to an electronic pilot pressure controller and a flow meter in a control loop. (See Fig.A.) To control flow, a proportional-integral-derivative (PID) controller monitors input from a flow transmitter (FT) and adjusts the pilot pressure. The electronic signal from the PID converts into a pressure signal for the pilot controller by an electro-pneumatic transducer (E/P). Increasing the pilot pressure reduces flow, and decreasing the pilot pressure increases flow. The system performs best when the supply pressure is stable.

- Flow coefficient (Cv) ranges wider than conventional valves (>100:1)

- Extremely low DP and extremely high DP

- Two-phase, phase-change, and supercritical states

- Continuous flow chemistry

- Sanitary applications

Tutorial for Setting the Siemens SITRANS P320/P420 for Level Measurement Applications

Control Performance Analytics - CPA

Control Performance Analytics - CPA

Automated Control Loop Analysis for Efficient Plant Optimization

CPA - What Is It?

Benefits of Control Loop Optimization Through CPA

- Increased product quality due to lower fluctuation in process variables

- Maximized equipment lifetime due to reduced variability in actors

- Improved set points raise throughput by going closer to the limits

- Resource savings thanks to improved set point tracking behavior (e.g., energy, raw material)

- Reduced manual mode of control loops allows overlaying control optimizations such as Advanced Process Control

- Fewer alarms and fewer operator interactions reduce operators‘ workload

Siemens CPA User Advantages

- PLANT-WIDE TRANSPARENCY

- Includes hierarchical plant overview, from management view to single control details for Siemens SIMATIC PCS 7 and other DCS.

- IMPROVED PLANT ASSET PERFORMANCE

- Identification of optimization potential as a result of correlating process data automatically with possible asset problems.

- FAST SETUP

- Intuitive interface enabling customer to use the application without extensive training.

- AUTOMATIC STATE DETECTION AND KPI CALCULATIONS

- Messaging behavior, service factor, steady state accuracy, set point tracking and static friction probability for various control states.

- COST BENEFITS

- Long-term process optimization and flexible managed service approach – pay only when you use the application.

- OPEN, CLOUD-BASED IOT OPERATING SYSTEM

- CPA is part of Siemen's Asset and Process Performance Suite for industrial applications and advanced analytics.

Compact Portable Samplers: The Foundation for Your COVID-19 Wastewater Surveillance Program

An effective COVID wastewater monitoring program relies on representative samples.

Water samplers are critical components in developing and deploying a community-based underground sewage surveillance program for COVID-19 outbreak detection, including best practices for wastewater sampling, lab analysis, and the immediate delivery of actionable information to local public health officials and administrators.

Wastewater testing refers to numerous water quality procedures examining wastewater's physical, chemical, and biological qualities.

Officials in certain areas are analyzing wastewater to see whether it contains Covid-19. The test looks for ribonucleic acid (RNA), Covid-19's genetic material, in feces found in sewage and wastewater.

SARS-CoV-2 causes Covid-19. According to studies, people with SARS-CoV-2 start spilling the virus in their feces shortly after infection. The virus's DNA enters the huge wastewater collecting network. The viral content of a community's wastewater may reflect the prevalence of Covid-19. Modern sampling and analysis methods can identify and quantify it up to a week before people test positive in clinics. Individual testing, contract tracking, and quarantine are possible mitigation and reaction methods. It also enables population sampling and monitoring of large-scale public health initiatives.

Analysis of viral concentrations in particular institutions such as nursing homes and college dormitories and neighborhoods or whole communities may help restrict the spread and avert additional harm.

The CDC created the NWSS in September 2020 in response to the COVID-19 pandemic. The CDC's National Watershed Surveillance System (NWSS) coordinates and increases the nation's ability to monitor SARS-CoV-2.

There may be a way to identify the new Coronavirus in low quantities in wastewater. Many states, including Colorado, Ohio, New York, and Wyoming, have successful Covid-19 wastewater testing programs. Universities and municipalities use this method to identify community hotspots. Multiple success stories have proven early identification and control using dorm wastewater monitoring and individual COVID testing. These universities were among the first to use COVID patterns in wastewater to reduce community spread inside dormitories and across campus.

Representative samples facilitate COVID wastewater monitoring. For COVID-19 epidemic identification, water samplers are essential for wastewater collection, lab analysis, and quick distribution of actionable information to local public health authorities and administrators. These data disclose the population numbers in a specific geographic region to estimate the virus's prevalence and quantity in wastewater. Combine Hach® small portable samplers with laboratory testing for automated composite wastewater sample collection that may help avoid outbreaks.

VISIT THIS PAGE ON THE PTI WEBSITE FOR MORE INFORMATION ON THIS SUBJECT.

A Superior Method of Measuring Dissolved Oxygen in Pure Water Systems at Power Plants

PTI Salespeople Dan Taylor & Daniel Gibbs at Siemens Process Automation Training

The TriGas X5000 Integrated Gas Detection Solution

- NFPA 820: Standard for Fire Protection in Wastewater Treatment and Collection Facilities

- NFPA 497: Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas

- NFPA 70®: National Electric Code® when standard practice dictates separation of electronics from sources of gas leaks.

- Ultima X5000 sensors for O2, H2S and IR LEL combustible gas

- Designed for high-moisture environments

- NEMA 4X Stainless Steel or Fiberglass Enclosure

- SM5000 Sample Pump

- Red Strobe

- Buzzer

- Hydrophobic End-of-Line Filter

- Inlet/Outlet Flashback Arrestors