The Process Technology Blog provides educational and product information for the industrial process control and factory automation markets. Posts will include application information, new product announcements, How-To's, and process control education. This blog is sponsored by Process Technology, Inc. Contact PTI by calling 801-264-1114 or visiting their website at https://process-tech.com.

Siemens Level Instrumentation

Vibration Analysis and Wireless Vibration Solutions from Banner

Introduction: What is Vibration Analysis?

Vibration analysis studies vibration's frequency, amplitude, and damping in mechanical structures to detect and diagnose faults in machinery and industrial equipment. Vibration analysis aims to identify the source of a potential or existing problem and provide a solution to fix it.

What are the Different Types of Industrial Vibrations?

Industrial vibrations are a common occurrence in many industries. They cause damage to equipment, structures, and even people if not controlled. It's critical to understand different industrial vibrations and how to manage them and minimize their effect on people and equipment.

The different types of industrial vibrations are:

- Shock Vibration - This is when an object is suddenly moved or released, causing it to move rapidly back and forth.

- Random Vibration - An object moves randomly with no pattern or specific frequency.

- Steady State Vibration - Steady-state vibration occurs when an object moves at a constant rate with no change in amplitude or frequency.

- Random Excitation - This vibration occurs when something vibrates because it has been disturbed by some external force such as noise or wind.

- Resonance

Industrial IoT Control Panel Design

Introduction: What is IIoT and Why is it Important?

Wireless Networking for Connected Devices

Control Panel Design for IIoT Systems

- Solve issues with costs and difficulties in traditional hard-wiring.

- Quickly and locally identify process conditions and alert, alarm, or correct outputs to normalize the process.

- Efficiently deploy various instruments and controls to interact with the process.

- Provide easy-to-understand displays showing in-depth information.

- Provide real-time information to corporate information systems.

- Are easy to install anywhere, even in remote locations with no power supply.

- Are more flexible with their use and have applications in many industry types.

Discuss Your IoT Control Application with Process Technology, Inc.

SITRANS P Pressure Instrumentation by Siemens

Process Refractometers for Petrochemicals and Oil & Gas Refining

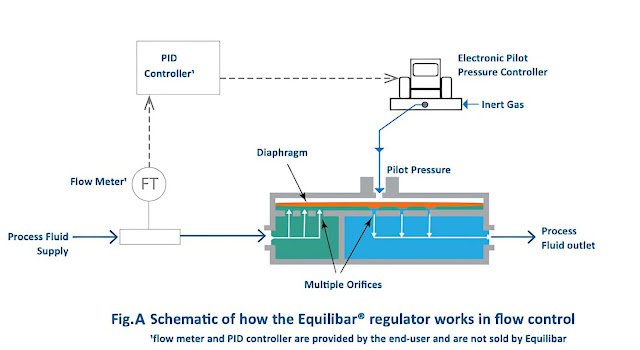

The Equilibar® Flow Control Valve

The Equilibar® flow control valve links to an electronic pilot pressure controller and a flow meter in a control loop. (See Fig.A.) To control flow, a proportional-integral-derivative (PID) controller monitors input from a flow transmitter (FT) and adjusts the pilot pressure. The electronic signal from the PID converts into a pressure signal for the pilot controller by an electro-pneumatic transducer (E/P). Increasing the pilot pressure reduces flow, and decreasing the pilot pressure increases flow. The system performs best when the supply pressure is stable.

- Flow coefficient (Cv) ranges wider than conventional valves (>100:1)

- Extremely low DP and extremely high DP

- Two-phase, phase-change, and supercritical states

- Continuous flow chemistry

- Sanitary applications